Description:

OilFieldScreens waste management decanter centrifuge is the premium centrifuge with the best material configuration. It is the best option for middle term and long term investment because of it’s reliability and working life. This series of decanter centrifuge are popular for the drilling waste management,oil sludge treatment, tank cleaning waste treatment, as well as solids control, barite recovery, Low gravity and high gravity solids separation, dewatering etc

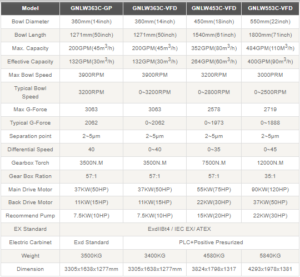

Specifications of OilFieldScreens Waste Decanter Centrifuge

OilFieldScreens Waste Decanter Centrifuge Features:

- High G Force up to max 3000. Big Volume Design.

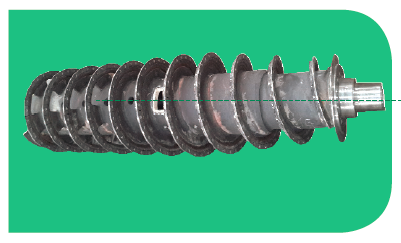

- Bowl Material Duplex Stainless Steel 2304 made from centrifugal casting.

- Conveyor Wear Surface: Tungsten carbide tiles .The life is much longer than hard surface. And all tiles is interchangeable for easy maintenance.

- Preasurized Explosiong Proof with PLC and HMI control for automatical operation.

- All the bearings for the centrifuge are SKF brand premium bearings.

OilFieldScreens Centrifuge for Drilling Waste Management

The drilling fluids recovered by the drilling cuttings dryer should go through the GNLW363 decanter centrifuge to reduce the solids content before returning to the active mud system. The GNLW363 decanter centrifuge can be used in WBM, SBM or OBM.

OilFieldScreens Centrifuge for Oil Sludge Treatment

The design of the centrifuge on the telescopic skid is popular for oil sludge separation, and waste management rental business. The telescopic skid height is adjustable, It allows the liquid discharged from the centrifuge goes to storage tank by gravity without a transfer pump.