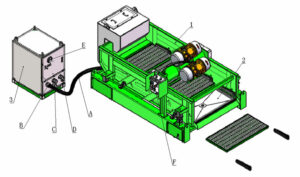

Description:

ViST is Vacuum Shaker Screen Technology is to work with shale shaker to reduce drilling waste and recycle drilling fluids.

The ViST Pan is installed under the last screen or mounted externally. And a suction hose is connected to ViST vacuum unit. The compressed air from air compressor or the rig air supply is required to create suction on the last screen surface, pulling additional fluid off the cuttings. It can reduce the liquid on the cuttings by 30-50%.

In a result ,ViST maximizes the volume of recovered and reused fluids and it provides dryer cuttings. Dryer cuttings mean less drilling waste and more recovery drilling fluids. So ViST can save money for operators on drilling fluids and waste management.

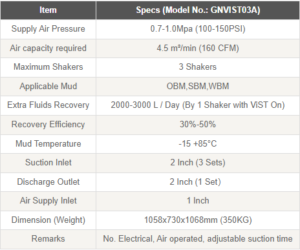

ViST Vacuum Screen Technology Specification

ViST Vacuum Shaker Screen Advantage:

- Widely application for OBM, SBM, and WBM.

- Both onshore and offshore application to reduce waste and recovery fluids.

- To replace High G drying shale shaker without any extra consumption of shaker screens.

- Less foot print and easy installation without welding.

- Reduce waste by 30% to 50%

- Finer shaker screen can be used to improve the solids control efficiency.

- Less cost for drilling cuttings transportation

- No electric power required, suitable for work in Hazardous area.

- The suction and discharge time is adjustable according to different drilling conditions.

- One ViST can be connected to 2 – 3 shakers with only one air supply to the ViST Vacuum unit