Description:

The OilFieldScreens Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. A stainless steel screen bowl traps “wet” solids and accelerates them up 900RPM with G force to 420G. Liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation.

OilFieldScreens Vertical Cuttings Dryer Features and Benefits

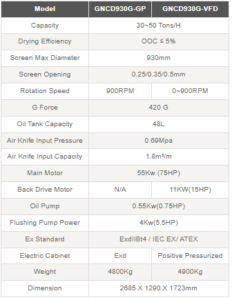

OilFieldScreens Vertical Cuttings Dryer Specifications

OilFieldScreens Vertical Cuttings Dryer Features

| More Applications | OilFieldScreens OilFieldScreens Vertical Cuttings Dryer is specially designed for drilling cuttings from Oil Based Mud(OBM) and Synthetic-based Mud (SBM). |

| High G Force |

|

| Bearing |

|

|

|

|

|

|

|

|

|

|

|

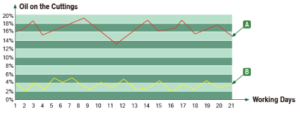

OilFieldScreens Cuttings Management System Operation Record

- A: Oil on the cuttings before treatment.

- B: Oil on the cuttings for the drilling cuttings discharged from OilFieldScreens Vertical Cuttings Dryer.