Description:

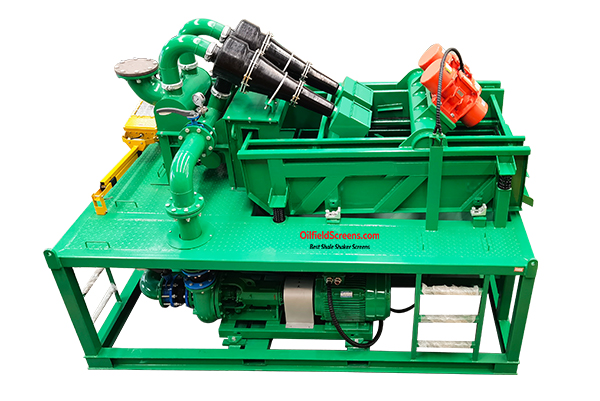

OilFieldScreens Desanding Plant is the economic way for mud recycling, it is popular for Bored Pile Slurry desanding plant, TBM slurry treatment, HDD (trenchless) as well as water well drilling etc.

OilFieldScreens Small Desanding Plants Models:

- OSMS-200D Capacity: 200GPM,50m³/h

- OSMS-500D Capacity: 500GPM,120m³/h

- OSMS-1000D Capacity: 1000GPM,240m³/h

OilFieldScreens Big Desanding Plants Models:

- OSMS-360M Capacity: 360 m³/h

- OSMS-500M Capacity: 5000 m³/h

- OSMS-1000M Capacity: 1000 m³/h

- OSMS-2000M Capacity: 2000 m³/h

- OSMS-3000M Capacity: 3000 m³/h

OilFieldScreens Desanding Plant Working Principle

The slurry pump sucks the mud from the mud pit, than enter into bottom layer screen of shale shaker (3) through buffer box(2), the coarse particles will be separated out and the mud flow to mud storage tank (4) through the bottom layer screen of shale shaker(3). The centrifugal pump (5) takes mud from the recycling tank(4), and feed to desander cone (6) with pressure for centrifugal separation, the solids/sand was discharged to upper shaker(3) from the outlet nipple of the desander cone. After dewatering process of the upper shaker(3), the fine solids was separated out. The mud passed the upper shaker screen returns back to recycling tank(4),the clean mud entered into intermediary tank(7) through desander cone overflow pipe. The mud in the intermediary tank (7) will go out through outlet pipe (9) or go back to recycling tank (4) depends on the fluid level in the recycling tank.

In the mud circulation process, there is a fluids level float switch (8) between intermediary tank (7) and recycling tank (4), it can balance the fluids level in the recycling tank(4). When mud level is low in the recycling tank (4) the overflow from the desander will enter recycling tank (4) through the intermediary tank (7). When the mud level is too high in the recycling tank (4), the mud will overflow to the intermediary tank (7) and go out from the outlet pipe (9). If operators want to get high quality clean fluids, the feeding capacity to the system can be reduced, and the repeat cleaning process will to get the result.

OilFieldScreens TBM Slurry Treatment Desanding Plant

As OilFieldScreens Manufacture shale shakers, desanders, desilters, decanter centrifuges. So OilFieldScreens Control is able to provide complete solutions for TBM slurry treatment project.

The shale shaker for separation coarse solids, the desander for separation sands, the desilter for separation silts, the mechanical centrifuge for separation fine solids.The chemically enhanced technology with decanter centrifuge for separation ultra fine solids to discharge water.