Oil Sludge Treatment Equipment

OilFieldScreens Oil Sludge Treatment equipment is to use chemical to wash the oil sludge with heat to temperature of 60-70 C degree. After washing the sludge is pumped toOilFieldScreens equipment to separate into oil, water and solids. The recycled water can be reused in the washing process, and the oil is clean enough to sell to the refinery company, the solids contain oil between 2%-5% which can be sent to biodegradation or thermal unit for final disposal.

Description:

OilFieldScreens Oil Sludge Treatment equipment is to use chemical to wash the oil sludge with heat to temperature of 60-70 C degree. After washing the sludge is pumped to OilFieldScreens to separate into oil, water and solids. The recycled water can be reused in the washing process, and the oil is clean enough to sell to the refinery company, the solids contain oil below 2% which can be sent to biodegradation or thermal unit for final disposal.

The typical oil sludge is as below:

- Crude Oil tank cleaning sludge

- Refinery plant waste oil sludge

- Drilling waste oil sludge

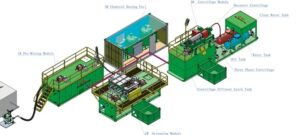

OilFieldScreens Oil Sludge Treatment Layout Drawing

Main Equipment for the Oil Sludge Treatment

| S/N | Equipment | Description |

|---|---|---|

| 1 | Solids Vacuum Pump | For suction of oil sludge from the pit or tank |

| 2 | Pre-Mixing Tank | Heat and mixing the oil sludge |

| 3 | Shale Shaker | Separate the coarse solids |

| 4 | Decanter Centrifuge | Removal of fine solids |

| 5 | 3 Phase disc separator | Separation of oil, water, solids |

| 6 | Chemical Dosing System | Provide chemical for enhancing the separation |

OilFieldScreens Solids Control is one of the few companies who have experience in both China and international market for the oil sludge treatment. Our equipment is field proven technology for oil sludge treatment to recovery oil and water and reduce the waste solids.

Following oil sludge treatment system is the typical size.

| Model | Capacity |

|---|---|

| GNOST-01A | 1-2 m3/h |

| GNOST-05A | 5m3/h |

| GNOST-15A | 15m3/h |

| The capacity above is for oil sludge after premixing with solid content below 20% | |