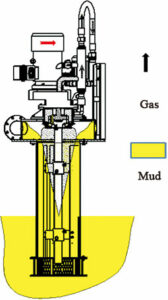

Via the rotating impeller, the degasser sucks the drilling fluid into the vessel. The fluids will stay at a level higher than the gas cut drilling fluid and then a cylindrical liquid layer with inverted cone shape space in the middle will be formed. Drilling fluid is discharged from discharge port along a tangent line. With the impeller rotating, bubble breaks, gas will be extracted from liquid, and finally accumulate in the cone shape space as the lower density. Pressurizing unit(similar to exhaust fan) will suck air through the narrow channel between the air distribution disk and air separation ring into the discharge cone, and then gas manifold, braided hose and pressurized device to pressuring unit, finally discharge the gas out through pressuring device with pressure.

Centrifugal Degasser

GNLCQ300A centrifugal degasser is a new type degasser, specialized in processing gas cut drilling fluid. Normally it is installed after shale shaker and widely used in various solids control system, and it is very important for recovering mud weight, stabilize mud viscosity performance, reduce drilling cost.

Description:

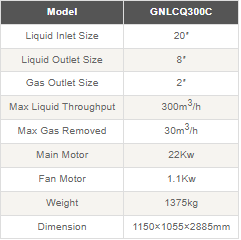

GNLCQ300C centrifugal degasser is a new type degasser, specialized in processing gas cut drilling fluid. Normally it is installed after shale shaker and widely used in various solids control system, and it is very important for recovering mud weight, stabilize mud viscosity performance, reduce drilling cost. Meantime it can be used as a big power blender. Its advantages are large capacity, high rate of degassing, less area required, low energy consumption, easy operation and maintenance.

Centrifugal Degasser Parameter

OilFieldServices Centrifugal Degasser Working Principle