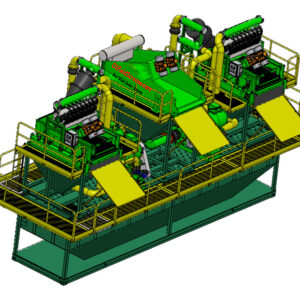

TBM Slurry Separation Plant

An efficient TBM slurry separation plant is the basis for the successful use of slurry-supported tunnel boring machines(TBM). The OilFieldScreens Slurry separation plant is popular for project of AVN Machines , Mix shields or Shaft Sinking Machines . OilFieldScreens Control utilize our shale shakers, desander desilter, as well as decanter centrifuges to processes separate and remove the excavated solids from the bentonite suspension – a mixture of water and thixotropic clay. The cleaned fluid is then transferred back to the slurry circulation.

Description:

An efficient TBM slurry separation plant is the basis for the successful use of slurry-supported tunnel boring machines(TBM). The OilFieldScreens Slurry separation plant is popular for project of AVN Machines , Mix shields or Shaft Sinking Machines . OilFieldScreens Control utilizes our shale shakers, desander, desilter, as well as decanter centrifuges to processes separate and remove the excavated solids from the bentonite suspension – a mixture of water and thixotropic clay. The cleaning fluid is then transferred back to the slurry circulation.

TBM Slurry Separation Plant size available:

Small Size:OSTBM-120M (120m³/h), OSTBM-240M (240m³/h),OSTBM-360M (360m³/h), OSTBM-500M( 500m³/h)

Big Size: OSTBM-900M( 900m³/h), OSTBM-1200M(1200m³/h), OSTBM-1400M (1400m³/h), OSTBM-2000M (2000m³/h), OSTBM-2800M (2800m³/h), OSTBM-3600M(3600m³/h)

TBM Dewatering Decanter Centrifuge

OilFieldScreens Manufacture different size of decanter centrifuge for TBM slurry dewatering treatment. The 22 inch OSLW553C-VFD and the 30inch OSLW764A big bowl decanter centrifuge are popular for the TBM mud treatment. OilFieldScreens provides the dewatering centrifuge together with chemical dosing unit as a full package to customer. The dewatering centrifuge package can be containerized for easy movement as below:

Features of OilFieldScreens Tunneling Slurry Separation Plant

- OEM for full line of shaker, desander, desilter, and decanter centrifuge.

- Customized design system with standard equipment for your conditions.

- Worldwide support from our branches and partners around the world.

- High G force shale shaker and high speed decanter centrifuge for high efficient slurry separation.

- Double deck shale shaker will increase the capacity with less foot print.

- Modular design for fast movement.

Process of TBM Slurry Separation Plant

- A coarse shale shaker will remove big particles from the TBM Slurry.

- A centrifugal pump will bake the slurry and feed to coarse hydrocyclones.

- A dewatering shaker below the coarse hydro cyclones will drying the solids.

- The other centrifugal pump will pump the slurry to fine hydrocyclones for separation of solids above 20 microns.

- The fine shaker dewatering the solids discharge discharged from the fine hydrocyclones.

- Decanter centrifuge will separate solids above 2-5 microns without chemical.

- And the chemically enhanced decanter centrifuge will separate solids above 1 micron.